Description of LYHO’s heat exchange product parts

Thread pipes

Bent pipes (U-tubes)

Assembled external frames

Fitting pipe combination

High-pressure connection design

High structural variability

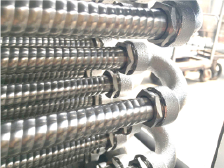

Thread pipes

The heat exchange area of the smooth tube is increased by 5-10%, with the industry’s thinnest thickness of only 0.5mm. The heat transfer efficiency is no less than the copper tubes, while the spring effect leads to scaling naturally falling off. The long-term use efficiency remains at 100%.

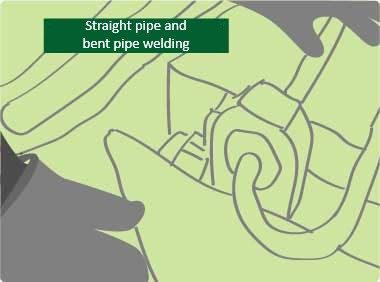

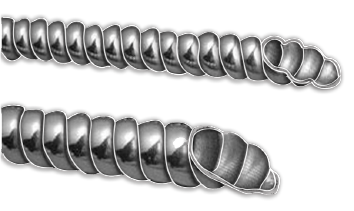

Bent pipes (U-tubes)

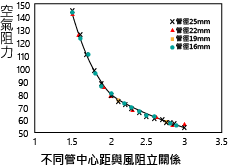

The center distance is only the industry’s smallest of 50 mm, which substantially decreases the machine volume. The smooth bent pipe technology reduces the water flow resistance by 25%, enhances efficiency, and increases the service life of cycle pumps, saving power by more than 15%.

Assembled external frames

Featuring convenient on-site assembly, transportation costs are reduced by 75%. Direct onsite disassembly and repair can be achieved, thereby reducing post-service costs by 50%.

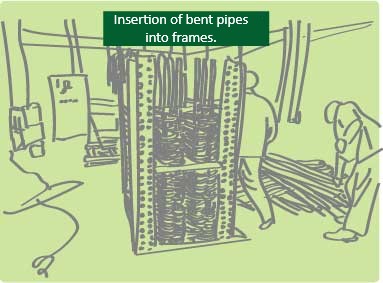

Fitting pipe combination

During repair, dismantling and replacement of whole coils are not required. Instead, only damaged accessories need to be replaced, which decreases the repair time by 50% and reduces maintenance costs.

High-pressure connection design

The coil and pipe connection can reach a pressure of 25 kg/cm2, the highest pressure-resistance int eh industry. There is no need to worry about the risk of instantaneous pressures that cause pipe burst, neither is there any safety concern.

High structural variability

The changeful styles meet customers’ needs. Products are customized to cater to customers’ needs, while exclusive products are manufactured independently.

LYHO’s close cooling tower-The closed-loop cooling tower uses water as the medium. Through the principle of circulation, the temperature is lowered to achieve the purpose of energy conservation.

In addition to providing overall closed-loop cooling tower planning, customized tube bank design modules are also provided, which are intended for various industrial applications.

Advantages and disadvantages of LYHO heat exchangers

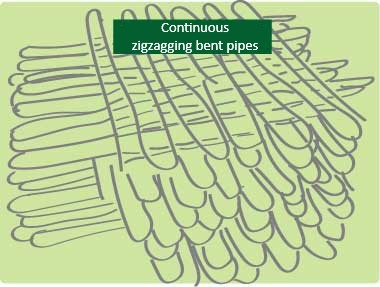

Conventional practices-Continuous S bent tube banks

- Straight pipes need to be light pipes.

- Straight single tubes must be at least 12 m in length.

- To cater to U-bend stretch, the wall thickness should be at least 1.0 mm.

- Since it is a long-distance continuous U-bend, the core cannot be connected, thus a greater radius and tube center distance.

- Factor welding and pressure testing are required for overall delivery upon completion.

Disadvantages

The straight pipes are light pipes, unable to strengthen the form of heat transfer. The straight single tubes must be over 12 mm in length. To cater to U-bend stretch, the wall thickness must be more than 1.0 mm, which is heavier with poor heat transmission. Since the core cannot be connected due to the long-distance continuous U-bend, the tube distance cannot be freely adjusted, factory welding and pressure testing are required before overall delivery.

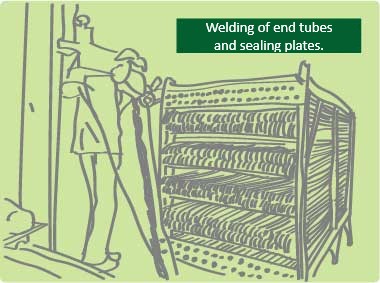

Conventional practices: Welding of tube banks.

- Since the auto-weld, the thickness of straight pipes should be above 0.7 mm.

- There are many welding points that require multiple leakage tests.

- Factory welding and pressure tests are required before overall delivery to the construction site.

- The tube distance arrangement is more fixed.

- The volume specifications are more fixed.

Disadvantages

Since the auto-weld straight pipe thickness is above 0.7 mm, the welding point requires multiple leakage tests. Complete factory welding and pressure testing before overall delivery, without saving time and delivery labor during construction. The pipe distance arrangement therefore lacks freedom.

Advantages of LYHO tube bank module products

Tube material-stainless steel pipe

(1) Impact resistance and corrosion resistance superior to copper tubes.

The stainless tube strength and surface hardness are higher than those of copper tubes. The most apparent characteristic is the enhanced ability to resist sediments on the water side, inlet turbulent flow, and the impact and erosion of water droplets from the air stream during the operation process of the cooling hose. Moreover, a higher in-pipe flow rate can be adopted.

(2) Anti-vibration

The in-pipe and fan operations are the main causes contributing to pipe vibrations. Since the rigidity of stainless steel pipes is greater than that of copper pipes and that stainless steel thread pipes have greater strength compared to light pipes, the anti-vibration property will be superior to copper. Furthermore, the flexible modularity of stainless pipes is superior to that of copper, the tensile strength is greater, thus better able to withstand the axial tensile force compared to copper tubes, thereby allowing a greater span between tubes and sheets.

(3) Anti-corrosion

Copper pipes are extremely sensitive to chemicals and potential difference corrosion generated by cooling water. This is also the main cause of copper pipe leakage. Stainless steel pipes on the other hand are highly resistant to acid and alkali corrosion. Additionally, the excellent corrosion resistance of stainless steel can effectively prevent the harmful gases from eroding the cooling pipes.

(4) Anti-scaling

The internal and external surface of the stainless steel thread spiral tubes. Compared to copper alloy tubes, stainless tubes have less corrosion derivatives, with clean pipe walls and unlikeliness to form scales. In addition, the dirt layer and stainless steel vary greatly in the thermal expansion coefficient. When subject to heat, the linear curve change differs and automatically fall off, thereby maintaining sound cleanliness.

Mechanical properties of stainless and cooper

| Material type | Yield strength MPa | Tensile strength MPa | Elongation% | Hardness HRB | Density g/ | Thermal conductivity W/m.K | |

| Stainless steel |

JIS SUS304 TP304 JIS SUS316 |

≧205 ≧205 ≧170 |

≧520 ≧515 ≧485 |

≧40 ≧40 ≧40 |

≦90 ≦90 ≦95 |

7.93 8.1 7.98 |

16.3 15.8 16.3 |

| Copper pipe | JIS H3300 | ≧147 | ≧205 | ≧40 | ≦60 | 8.94 | 33.9 |

Comparison table of corrosion types

| Corrosion types |

Yellow brass C2600 |

Alloy coppe JIS H3300:C6870T |

Red copper JIS H3300:C7060 |

Red copper JIS H3100:C7150 |

Stainless steel SUS304 |

Titanium(Ti) JIS H670 |

| General corrosion | 2 | 3 | 4 | 4 | 5 | 6 |

| Erosion | 2 | 2 | 4 | 5 | 6 | 6 |

| Cavitation (flow) | 4 | 4 | 6 | 5 | 4 | 6 |

| Cavitation (still water) | 2 | 2 | 5 | 4 | 1 | 6 |

| Water erosion | 3 | 3 | 4 | 5 | 6 | 6 |

| Water inlet impingement attack | 2 | 2 | 3 | 4 | 6 | 6 |

| Vapor impingement attack | 2 | 2 | 3 | 4 | 6 | 6 |

| Stress corrosion | 1 | 1 | 6 | 5 | 5 | 6 |

| Chloride corrosion | 3 | 5 | 6 | 5 | 1 | 6 |

| Ammonia corrosion | 2 | 2 | 4 | 5 | 6 | 6 |

| Microbial corrosion | 5 | 5 | 4 | 4 | 2 | 3 |

| Potential difference corrosion | 2 | 2 | 3 | 3 | 4 | 6 |

Heat exchange tube/pipe part-The thread design is adopted.

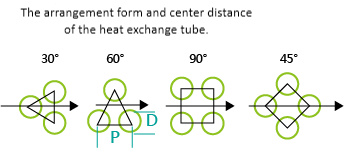

Since the first academic report on thread pipes released by Luwsun et al. (USA) in 1966, thread pipes as a high-efficiency heat exchange component have drawn great attention. Currently, they have become widely applied. LYHO’s heat exchange tubes/pipes adopt a thread pipe design. Thread is a type of internally convex and internally concave spiral heat pipe. For the equipment, the cold roll forming method is adopted to process ordinary light pipes into thread pipes. Heat exchange tubes/pipes applicable for boilers, condensers, low-pressure heaters, oil coolers, air coolers, and other heat exchange devices.

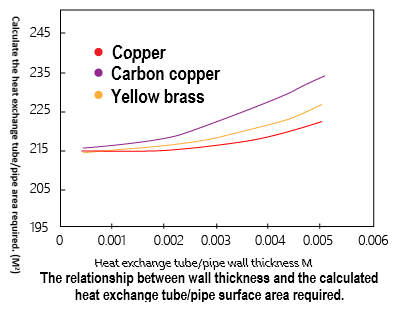

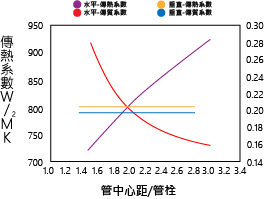

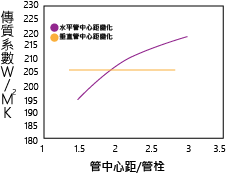

The internal thread aids in evenly mixing fluids in the pipes, reducing laminar flow, and increasing thermal resistance. In addition to increasing heat exchange surface by 8%, the external thread is also used to increase heat transmission efficiency and make scaling fall off. According to studies, the thinner the thickness of the heat dissipation pipe of the closed tower tube bank, the lower the difference and effect of heat transmission efficiency among materials. This finding can be verified from the diagram on the left and actual testing. The tube bank module designed by LYHO adopts this design principle to achieve the purpose of increasing the contact surface, thereby enhancing efficiency.

Our company adopts MIT SUS304 pipes measuring 19.05 mm in external diameter and 0.5 mm in thickness and self-processed thread design.

The bent pipe part-The smooth U-bend can be freely

arranged to increase the water contact surface area.

arranged to increase the water contact surface area.

Since conventional tube banks are welded in the factory, the welding point-to-point design arrangement will be limited. It can only be presented as stationary on the proprietor’s construction site, unable to have an effective design arrangement to suit local conditions. LYHO’s heat dissipation tube bank products are modularized to overcome conventional limitations, not limited by the construction stage.

Crutch design-Cost reduction, easy construction, convenient transport.

LYHO’s main feature of the tube bank design being superior to the conventional one lies in the crutch. LYHO is different thanks to its modular crutch design. In addition to reducing the transportation and assembly costs, modules are maximized through flexible applications and arrangements in response to proprietors needs, without being limited by the conditions of the construction site.

Featuring a crutch design, cost reduction

convenient transport and assembly.

convenient transport and assembly.