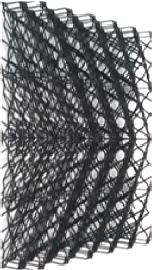

>PP temperature-resistant and dirt-resistant heat sink

This heat sink is specially intended for environments where cooling water quality is prone to dirt. In particular, cooing water contains grease, powder dust, and cotton, or the work status of hotter water cooling. Compared to conventional thin films and wooden heat sink, performance and cleaning convenience can be taken into account. The snap-in design is convenient to install and transport.

| Specifications of heat sinks | ||

| Material | Softening temperature °C | Thickness mm |

| PP | 150 | 1.8 |

| Specifications of heat sinks | |||||

| Water quality | Cooling tower type | Model No. |

Surface contact area m2/m3 |

Height of ripple mm |

Standard specification mm |

|

Industrial water (Max Tss:300PPM, 500PPM 10小時內) |

Counterflow typ | TL-NF 1900 | 125 | 19 | 500*450*305 |

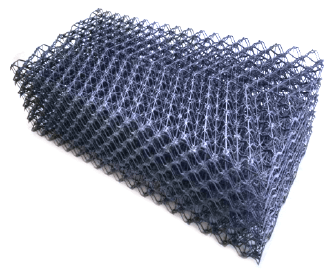

> PET FILM

This heat sink is specially intended for environments where cooling water quality is prone to dirt. In particular, cooing water contains grease, powder dust, and cotton, or the work status of hotter water cooling. Compared to conventional thin films and wooden heat sink, performance and cleaning convenience can be taken into account. The snap-in design is convenient to install and transport.

| Heat sink material | ||

| Material | Contact angle | Description |

| PET | 74 | More hydrophilic |

| PVC | 86.6 | |

| PET-S | 36.1 | Hydrophilic |

| Specifications of heat sinks | |||||

| Water quality | Cooling tower type | Model No. |

Surface contact area m2/m3 |

Height of ripple mm |

Standard specification mm |

| Industrial water | Counterflow-type cooling tower | TL-NF 1900 | 205 | 19 | 1830*305*305 |

| Industrial water | Counterflow-type cooling tower | TL-NF 1400 | 287 | 14 | 1830*305*305 |

| Industrial water | Counterflow-type cooling tower | Other brands of products | 150-160 | 19 | 1830*305*305 |

The apertures of heat sinks have been developed based on the most common specifications in the market, which are comparable to the pressure loss of windmills. The pattern design also takes into account the structural strength, which can withstand greater hydraulic impact and carrying capacity.